1. What is a Laboratory Padder? A laboratory padder (also called a lab padder or…

Tensile Strength Of Fabric – Strip Method

This post would mainly focus on the Tensile Strength Of Fabric – Breaking force and elongation – Strip Method

1. Tensile Strength Of Fabric Test Summary

Tensile strength – strip method is to test specified width strip sample by using tensile testing machine (CRE, CRE= CONSTANT RATE OF EXTENSION) to clamp it and separate in a certain speed until the sample is breaking. The breaking force and elongation at breaking will be recorded.

2. Tensile Strength Of FabricTest Standards

ASTM D5034, GB/T3923.1-2013, ISO13934-1:2013, ASTM D5035-11(2019) and etc.

3. Sample Preparation

Normally for woven fabric sample, reserve 5mm wide burr. The sample can be cut parallel to the radial or weft direction with a custom-made cutting die 60mm*250mm long side. The two test burrs of the sample are unraveled so that the sample forms a 50 mm wide sample.

For fabrics that cannot be removed from the side yarns, a 50mm wide fabric sample is cut by shearing.

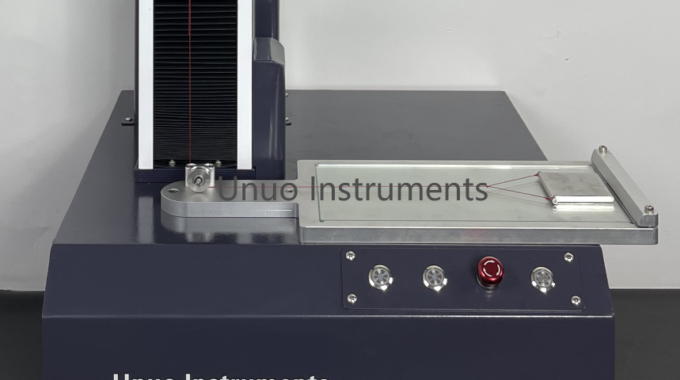

4. Fabric Tensile Strength Machine Requirements

The tensile machine’s speed should meet both 20mm/min & 100mm/min. And machine should be able to set grips width 100mm/200mm, accuracy ±1mm. The clamp surface should be able to hold the sample without slipping and without damaging the sample. When the plane clamp cannot prevent the sample from slipping, the clamp with texture can be used, but auxiliary materials must be attached to the surface of the texture to prevent damage to the sample. Clamp width should be wider than 60mm.

The tensile strength tester uses power control and data acquisition integrated circuits and software to process and obtain force and elongation data and tensile curves, and the data acquisition frequency is greater than 8 times/S.

The tensile machine can set the pre-tension, so that when it is stretched to the pre-tension, it starts to collect and process data to form a stretch curve.

5. Fabric Tensile Test Procedure

For woven fabric whose breaking elongation≤75%, use spacing 200±1mm

For woven fabric whose breaking elongation>75%, use spacing 100±1mm

When the tensile speed elongation at break is less than 8%, use 20mm/min, and when 8≤, use 100mm/min.

Adjust the grips position, and make the spacing=200mm. Clamp the sample after condition on the grips, and make the length direction of the sample parallel to the tensile direction of the tester. Set the corresponding gauge distance, speed, pretension, breaking strength, and elongation of the tensile tester software.

At the beginning of the test, the sample is stretched uniformly in the direction of elongation until it breaks. The force/elongation data during the stretching process is processed by the data integrated circuit and software system and presented on the software interface to form a force/elongation curve. After the data is processed, the breaking strength and elongation are automatically calculated.

At the beginning of the test, the sample is stretched uniformly in the direction of elongation until it breaks. The force/elongation data during the stretching process is processed by the data integrated circuit and software system and presented on the software interface to form a force/elongation curve. After the data is processed, the breaking strength and elongation are automatically calculated.

6. Result Analysis And Factors Affecting Fabric Breaking Force And Elongation

The reasons for affecting the performance of the fabric can be analyzed by obtaining the breaking phenomenon, breaking strength and elongation of the fabric through the test of tensile machine. For example, the strength of the original yarn directly reflects the breaking strength of the fabric. By changing the yarn density of the yarn, and adding Twisting can effectively enhance the breaking strength. The difference in the structure of the fabric is also an important aspect that affects the breaking strength of the fabric. It can increase the number of interweaving yarns per unit area. Yes, there are more yarns per unit width, thereby increasing the strength of the fabric. It can also be added in the finishing stage. Suitable finishing agent or strong protectant may help to improve fabric strength.