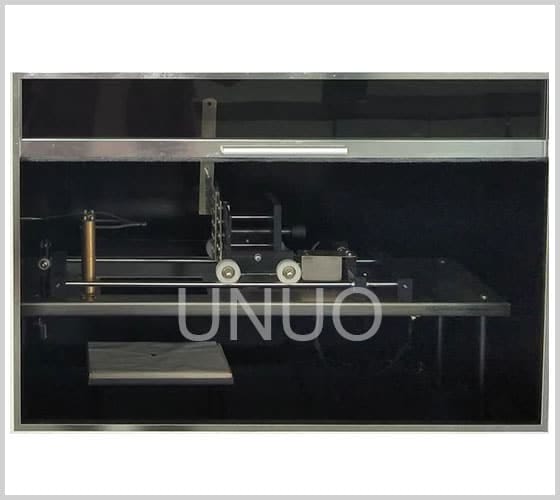

Glow Wire Test Apparatus UI-T234

Description

Glow Wire Test Apparatus is a flammability tester which uses heated glow-wire to contact specimen to see if the specimen will be ignited or not and calculate the specimen’s Glow-wire Flammability Index(GWFI) IEC 60695-2-12.

1. Unuo Glow Wire Test Apparatus Features:

- Automation:Unuo Glow wire test equipment is a piece of automation equipment that can send the test specimen back and forth automatically. Besides, it is a combination of test chamber and glow wire tester with a ventilation system, and a light system.

- Independent speeds:10mm/s & 25mm/s; speed to approach and withdraw are different by motor driven.

- Safety transparent cover: the safety cover is mainly to protect the operator from exhaust toxic smoke during the test. And for easier observation during the test, the safety cover is transparent.

- Glow wire is made of nickel/chromium(80/20) and diameter of 4mm. The glow wire is formed by a dedicated mold which can ensure its dimension/size accuracy. Glow wire is an important key component for the glow wire flammability tester.

- Timing Device: the timing device will count for the time of application of the glow wire, the time of ignition, the time of extinguishment

- The light inside of the chamber: the light inside of the chamber is the explosion-proof lamp, Osram or Philips 40W halogen lamp

- Mechanical system: the specimen loading system is driven by a stepping motor and controlled by PLC which can accurately locate the position and move at the required speed.

- The glow wire-loaded system is with 4 wheels, which will move on 2 tracks. The test impact force is 1N;

- Test fixture/grip: the grip is made of 304# stainless steel and Imported aluminum with an anode treatment which is strong and reliable. Equipped with high precision load, the applied force will be within test requirement according to IEC 60695-2-10 – Glow-wire apparatus and common test procedure

- The upgraded imported thermocouple is type K with a diameter of 1.0mm; Its service life is 2-3 times longer.

- The flame height measuring device is equipped

- Electrical circuit: the glow wire tester has an electrical circuit that has no feedback mechanisms or circuit to maintain the temperature.

- A reliable temperature control system can control the temperature tolerances within 2℃

- Equipped with current displayer;

- Standard black-painted inside chamber with a volume of 0.6CBM

- After the specimen is clamped and the safety cover is closed, all rest procedures are proceeded with outside of the chamber to avoid health hazards.

- Equipped with stainless tray and a wooden board to place tissue for molten drip

- Equipped with a copper brush for cleaning purposes.

- Ventilation: Unuo brand glow wire testing instrument has its own ventilation system on the top of the chamber. It is a completed glow wire test system.

Unuo Instruments supplies glow wire testing instrument at a reasonable price. Contact us today for a detailed quotation.

>>>>>More Flammability Tester Here

2. What Is Glow Wire Flammability Test? Why To Test?

Glow wire flammability test is to simulate if the overheated metal of electrotechnical products will lead to ignition and have the potential of fire risk or not. The overheated metal can be the ignition source of the electrotechnical products, and the heated glow wire can be the ignition source of the glow wire ignition test.

With aims to avoid fire risk, the component of electrotechnical products like its circuit, and materials, should be tested to know their ignition temperature and be reduced to an acceptable level of potential risks of fire. By the glow wire flammability test, the material’s glow wire flammability index(GWFI) can be determined which helps manufacturers to improve products and helps customers to choose suitable products.

3. Glow Wire Test Procedure

Loaded specimen on the grip and the glow wire will approach to specimen at a specified speed. The heated glow wire will touch the specimen with force 1N. Applied the heated glow wire for 30S. There is a position limiter for glow wire penetration in case it will penetrate too much into the specimen. Then remove it, observe for 30S to see if there is ignition or glowing combustion. Record the time, and check if it meets the standard requirement or not.

4. Glow Wire Test Method What Is ASTM For Glow Wire Test?

Glow wire test methods include IEC 60695-2-10, IEC 60950-1, IEC 60335-1, IEC 60884-1, IEC 60238, IEC 60695-2-11, IEC 60695-2-12, IEC 60745-1, IEC 60400, IEC 60730-1, IEC 60598-1, IEC 61050, IEC 60320-1, IEC 61058-1, IEC 60742, IEC 60669-1, UL 746A, BS EN 60695-2-1, BS 6458, NF C20-921-1, IS:11000, GB 5169, ISO, EN ETC. ASTM method for glow wire test is ASTM D6194

5. What Temperature Is Glow Wire Test?

For glow wire ignition test, the glow wire should be heated to one of the below temperatures as the initial test temperature. If you are not sure about the temperature, then use a temperature of 650℃ or below 650℃.

|

Initial Test Temperatures ℃ |

Tolerances |

|

550℃ |

±10℃ |

| 600℃ |

±10℃ |

|

650℃ |

±10℃ |

|

700℃ |

±10℃ |

|

750℃ |

±10℃ |

|

800℃ |

±10℃ |

|

850℃ |

±10℃ |

|

900℃ |

±10℃ |

| 960℃ |

±10℃ |

For glow wire test temperature, the minimum test temperature is 550℃, and the max test temperature is 960℃. Use 3 specimens as 1 set to test a temperature. If one specimen is failed to withstand a temperature, there is no need to test the rest 2 specimens.

If a set of specimens can withstand a temperature, for example, 550℃, then add 50℃ for the next test (60℃ for 900℃).

In the final process to test the max temperature, add 25℃ as the interval. (30℃ for 960℃)

6. What Is The Difference Between Glow Wire Test And Needle Flame Test?

The main difference between glow wire test and needle flame test is their ignition source. Glow wire test is using heated glow wire without flame, and needle flame test has a flame.

Unuo Instruments offers good glow wire test apparatus price. If you are looking for glow wire test apparatus t4-08, Unuo brand glow wire test machine would be a good option for you.