This post would mainly focus on the Tensile Strength Of Fabric - Breaking force and elongation…

Durometer Hardness Test By Shore Durometer – Unuo

1. Durometer Hardness Test

Durometer hardness test is to test the hardness of materials by shore hardness scale/shore durometer. The durometer is suitable to test thermoplastic elastomers, vulcanized(thermoset) rubber, elastomeric materials, cellular materials, gel-like materials, and some plastics.

2. What Is Shore Hardness

Shore hardness is referring to the hardness test result tested by the shore durometer which is named after its inventor– Albert Ferdinand Shore.

3. Shore Hardness Measurement Method

Insert the material to be tested with a Shore hardness tester, the pointer on the dial is connected to a needle through spring, and the needle is pierced into the surface of the tested object, and the value displayed on the dial is the hardness value.

4. Durometer Hardness Unit

Tested by durometer, a value after the test will be read which ranges from 0 to 100, but this shore hardness is not a unit of measurement. In other words, the shore hardness test is a dimensionless measurement. For example, if we use shore A durometer to test a sample, and get a 60 shore A, it means how hard the sample is when compared with other samples which are tested by the same shore A durometer. We can say that shore hardness is a relative hardness.

5. Durometer Hardness Scale

Durometer hardness scale includes A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R as listed in ASTM D2240 to meet different materials’ properties. Every type of durometer has a dial that ranges from 0 to 100. A higher value means a harder material. Recommended measure range is 20-90. When using a Shore A durometer, its value is less than 20HA, then an AO durometer is recommended. When its value is greater than 90HA, shore D is recommended.

6. Portable Durometer

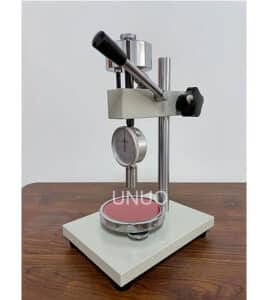

Unuo Shore durometer is a type of small hardness tester which is portable and easy to carry.

6. What are Shore A and Shore D Hardness

Shore A and shore D are 2 types of durometers that are most commonly used. Shore A is used for flexible soft types of materials while shore D is used for rigid/hard types of materials.

When tested with shore A, a force of 1kg should be applied for 15s, and 5kg for shore D. We, Unuo Instruments, supply the shore durometer and its test stands. Find more about shore durometer and durometer test stand below.

7. Hardness Of Rubber Is Measured On Which Scale

Shore A scale and shore D scale are most commonly used to measure the hardness of rubber.

8. How to Choose a Shore Durometer

The below table is from ASTM D2240.

TABLE X1.1 Durometer Selection: Typical Uses

| Type

(scales) |

Typical Examples of Materials Tested | Durometer Hardness

(Typical Uses) |

| A

|

Soft vulcanized rubber, natural rubber. ntriles, thermoplastic elastomers, flexible polyacrylics and therrnosets. wax, felt, and leathers | 20-90A |

| B | Moderately hard rubber. thermoplastic elastomers. paper products. and fibrous materials | Above 90A

Below 20D |

| C | Medium-hard rubber, thermoplastic elastomers. medium-hard plastics and thermoplastics | Above 90B

Below 20D |

| D | Hard rubber, thermoplastic elastomers. harder plastics, and rigid thermoplastics | Above 90A |

| DO | Moderately hard rubber. thermoplastic elastomers, and very dense textile windings | Above 90C

Below 20D |

| M | Thin. irregularly shaped rubber, thermoplastic elastomer, and plastic specimens | 20-85A |

| O | Soft rubber, thermoplastic elastomers. very soft plastics and thermoplastic, medium-density textile windings | Below 20 DO |

| OO | Extremely soft rubber, thermoplastic elastomers. sponge. extremely soft plastics and thermoplastic. foams, low-density textile windings, human and animal tissue | Below 20 O |

| CF | Composite foam materials such as amusement ride safety cushions, vehicle seats, dashboards, headrests, armrests, and door panels | See Test Method F 1957 |

9. How to Perform Shore Hardness Test? | Test procedure

Sample before shore hardness test should be treated under specified temperature and humidity conditions as per test standard requirements. Place the sample on a stable plate, the test point should be at least 12mm away from the sample edge. Press the durometer on the sample stably, without vibration, and Make the press foot parallel to the surface of the specimen so that the press foot can be pressed into the sample vertically and have an indentation. Read the value within a certain period, vulcanized rubber for 3 seconds and thermoplastic rubber for 15 seconds or as specified.

We suggest using the shore durometer with a test stand. By testing with a test stand, the parallel between the press foot and test plate, and the applied force(1kg or 5 kg) can be ensured.