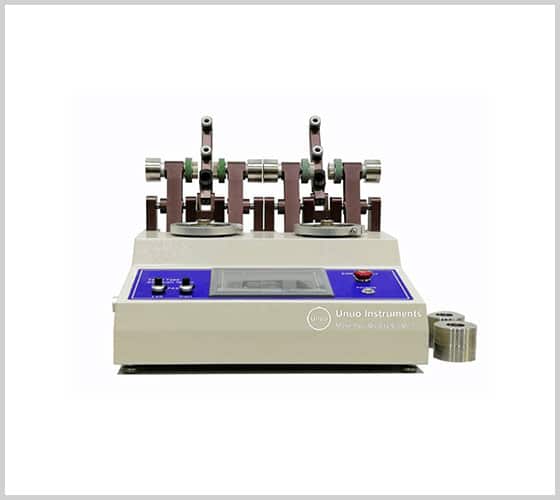

Bennewart Flex Tester UI-FT26

Description

Bennewart Flex Tester is used to test outsole flexing resistance by flexing the outsole at a certain speed and angle. The shoe outsole flexing method aims to check the effect of sole materials and surface patterns on cut growth. This whole sole flexing tester methods meet ISO 20344, ISO 17707, DIN 53543 and etc.

1. Unuo Bennewart Flex Tester Features

- Test Positions: 1, 3, 6 for choice. Customized positions supported.

- Test position can be made in Vertical or horizontal direction.

- Safety Cover is equipped to protect the operator.

- Shoe sole flexing tester with temperature control available;

- Brand motor to ensure long service life.

2. Notice for Outsole Flex Resistance Test:

Before the outsole flex resistance test, the outsole test sample should be test on outsole rigidity tester. Outsole which needs more than 30N to reach the angle of 45° is not suitable to flex on the whole sole flexing tester.

3. Bennewart Flex Test Procedure:

Remove the heel from the outsole and clam the outsole according to the standard. Make sure the outsole would be fully flexed in the right position. Then to cut the sample with an equipped chisel(cutting cool) to the required length, the cut should be parallel to the bennewart flex machine. Pre-set the machine to run 30,000 cycles. After it finished the pre-set cycles, check the cut growth and any change of the outsole. For more information, welcome to contact us at any time!

4. Bennewart Flex Tester Key Specification:

| Model | UI-FT26 |

| Test positions | 1, 3, 6 or customized |

| Standard | ISO 17707, DIN 53543, ISO 20344, SATRA TM161,

ISO20347 section 5.8.4, AS/NZS 2210.2 section8.4.2, QB/T 2885, |

| Clamp spacing | 110 ± 1 mm, width 155 mm |

| Flexing roller diameter | 30 ± 0.1mm |

| Movable clamp moving stroke | 41.5 ± 0.5 mm |

| speed | 135-150 cycles/min |

| Angle | (90±2)° |

| Counter | LCD display 0~99,999,999 can be set |

| Power | 1∮ AC 220V 3A |